OGI GasCore

![]()

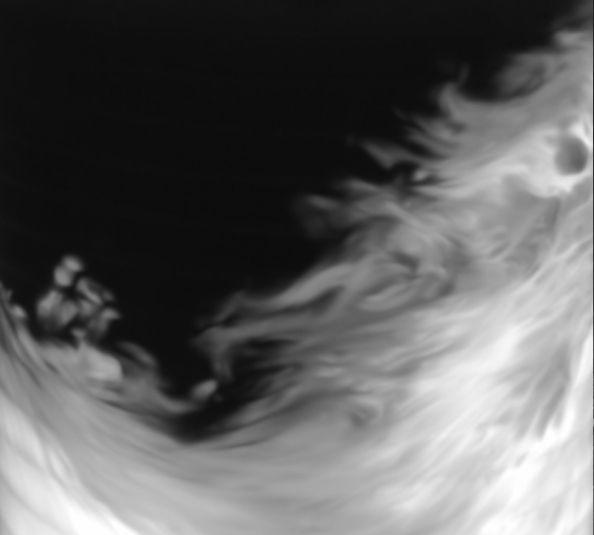

GasCore defines a series of high performance Optical Gas Imaging cameras based on the NoxEngine Technology.

OGI GasCore

Contacter les ventes ou demander un devis

Contactez-nousSelect your ideal configuration together with our experts

Each integration project is unique, and many configurations are available depending on your specific requirements, distance to the observed scene, available integration volume, autonomous use, or the need to interface with the mission or system computer.

That's why our team supports you from the very first steps, helping you define the setup that best fits your technical and operational needs.

Our team of experts will provide you with the necessary factual information to understand and choose among different technologies, interfaces, protocols, and image processing features. They will help you optimize your development efforts or suggest modifications to ensure the successful integration of your high-performance infrared cameras.

To benefit from personalized guidance and design the ideal solution for your application, get in touch with us. We'll determine together the right configuration for your mission.

Description

GasCore defines a series of high performance Optical Gas Imaging cameras based on the NoxEngine Technology.

Equipped with the latest generation of thermal infrared detectors, cooled by stirling engine, and ultra fast optics, GasCore cameras offer unmatched gas detection performance and flexibility in a reduced footprint.

Radiometrically calibrated, GasCore provides measurement data of impressive accuracy in a small and easy to integrate package

Sensing Configurations

GasCore33

Methane, Methanol , Propane, Benzene, Ethane, Propylene; Ethanol, Pentane, 1-Pentene, Isoprene, Butane, Ethylbenzene, Toluene, Octane, Heptane, Xylene, Ethylene, Hexane

GasCore39

Optimized for furnace inspection

GasCore43

CO2

GasCore46

CO, Acetonitrile, Acetyl cyanide, Arsine, Bromine isocyanate, Butyl isocyanide, Chlorine isocyanate, Chlorodimethylsilane, Cyanogen bromide, Dichloromethylsilane, Ethenone, Ethyl thiocyanate, Hexyl isocyanide, Ketene, Methyl thiocyanate, Nitrous oxide

GasCore105

Acetic acid, Acetyl chloride, Allyl bromide, Allyl chloride, Allyl fluoride, Anhydrous ammonia, Bromomethane, Chlorine dioxide, Ethyl cyano- acrylate, Ethylene, Freon-12, Furan, Hydrazine, Methylsilane, Methyl ethyl ketone (MEK), Methyl vinyl ketone, Propenal, Propene, Sulfur hexafluoride, Tetrahydrofuran, Trichloroethylene, Uranyl fluoride, Vinyl chloride, Vinyl cyanide, Vinyl ether

Technical Information

- Video Output Format :

- Color HDMI 720p with color overlay

- Optional SDI or Analog - Video Streaming :

- h.264 : RTSP or UDP

- RAW : GigEVision - Control :

- RS232 or Ethernet IP

- Cooled, snapshot FPA

- Spectral Range : MWIR – 3μm to 5μm or LWIR – 7μm to 10μm

- Matrix size : 320 x 256 pixels

- Pitch 30μm

- Fast Optical aperture

- Cooling by Rotary Stirling

- Cooldown Time @20°C <6min