Gamma ionization chambers

In gamma detectors, gamma radiation interacts with the cathode material and the filling gas, producing electrons. These electrons generate a charge that is collected and transmitted as direct current to the measurement electronics for further analysis.

Within these detectors, gamma or X-ray radiation interacts with the electrodes and filling gas, producing charged particles. The generated charge is collected and measured as direct current within the associated electronics

Gamma ionization chambers

Contact sales or request a quote

Contact usTechnical Information

| Product[a] | Diameter (mm)[b][c] | Sensitive Length (mm)[b][c] | Sensitivity[b][d] (A/Gy/h) | Material | Fill Pressure (Bar) | Typical Fill Gas | Type[f] |

|---|---|---|---|---|---|---|---|

| CRGE10 | 7 | 15 | 4.5x10-13 to 4.2x10-11 [e] | Stainless Steel | ≤10 1 | Xe, N2 | Miniature |

| CRGA11 | 18 | 150 | 1.6x10-10 [e] | Stainless Steel | 1 | N2 | Tubular |

| IG20 | 29[k] | - | ≈3.0x10-14 | Stainless Steel | 5.8[z] | Ar/N2/He | Spherical |

| IG34 | 35 | 46[y] | 1.71x10-8 | Stainless Steel | 20[z] | Xe | Tubular |

| IG35 | 35 | 46 | 5.6x10-10 | Stainless Steel | 1.6[z] | Xe | Tubular |

| CRGJ16 | 42 | 120 | 4.7x10-8 [e] | Stainless Steel | - | - | Tubular |

| CRGB10 | 48 | 30 | 5.6x10-10 to 6.7x10-8 [e] | Stainless Steel | 15 1 | Xe, N2 | Tubular |

| IG26 | 51 | 110 - 368 | ≈2.3x10-8 to 1.1x10-7 [g] | Stainless Steel | ≤50[z] | Various[h] | Tubular |

| IG1 | 90 | 115 | ≈2.1x10-9 to 9.1x10-8 [g] | Stainless Steel | ≤20[z] | Various[h] | Domed[i] |

| IG21 | 95 | 126 | ≈2.3x10-8 to 2.6x10-7 [g] | Stainless Steel | ≤50[z] | Various[h] | Domed |

| IG47 | 120 | 100 | 5.5x-8 A/Sv/h | Stainless Steel | 10[z] | Argon | Through-hole |

| IG48 | 150 | 176 | 1x10-4 C/Sv | Polyethylene | Ambient | Air | Tubular |

| IG5 | 186 | 350 | ≈1.4x10-7 to 1.7x10-6 [g] | Mild Steel | ≤40[z] | Various[h] | Domed[i] |

| IG5T | 183 | 350 | ≈9.8x10-8 to 1.2x10-6 [g] | Mild Steel | ≤15[z] | Various[h] | Domed[i] |

| IG11 | 185 | 322 | ≈1.0x10-6 to 1.9x10-6 [g] | Mild Steel | ≤20[z] | Various[h] | Re-entrant |

| IG12 | 185 | 320 | ≈7.5x10-9 to 1.6x10-6 [g] | Mild Steel | ≤20[z] | Various[h] | Re-entrant |

| IG32 | 185 | 48 | 1.43x10-7 | Mild Steel | 3.1[z] | Argon | Parallel Plate |

| IG42 | 190 | 293 | - | Aluminium | ≈11.3[z] | Nitrogen | Through-hole |

[a] Significant catalogue of ionisation chamber designs and variants available. Table shows the most popular variants

[b] Nominal values stated

[c] Excludes any containment and/or termination compartments

[d] Measured against 137Cs and utilising standard tolerance of ±20%, unless otherwise stated. Assumes 1 Gray = 114 Roentgen

[e] Assumes 137Cs is 93% of 60Co sensitivity

[f] Design, materials and manufacturing process are common among most of these devices. Consequently, operation capability is common and may be transferable

[g] Subject to specific configuration

[h] Typical or maximum value stated. Alternative available, subject to requirement and 2014/68/EU. Common gas types utilised: Ar, N2, Air, H, Ne, Kr, Xe or mixtures thereof

[i] Domed design allows for a more uniform polar response

[k] Spherical section only

*Sensitivity is approximately proportional to filling pressure

Description

Gamma ionization chambers are used in a variety of scientific, nuclear, and safety-related applications such as radiation area monitors, fuel re-processing, health physics, and research activities at labs and reactors worldwide. Detection sensitivity depends on the gamma energy and electrode materials, as well as the filling gas type and pressure.

Enhancing Safety with Exosens’ Gamma Ionization Chambers

Detection and measurement of gamma radiation play a pivotal role in various scientific, health physics and nuclear applications. Our Gamma Ionization Chambers are designed to provide accurate measurements of gamma radiations across a range of intensities and energies, catering to the unique needs of our customers.

Key Features:

- Exceptional reliability and extended operating lifetime to ensure long-term performance in critical applications Customization options to meet specific user requirements, from radiation area monitoring to laboratory experiments.

- Optimized detection sensitivity and energy response

At Exosens we recognize the importance of precision in scientific endeavours. Engineered for minimal leakage currents and optimal sensitivity, our Gamma Ionization Chambers offer a broad range of operational flexibility, tailored to meet the needs of your specific application.

Custom Gamma ionization chambers

By full control of the following processes, Exosens can supply custom gamma ionization chambers with the highest quality and reliability.

- Adaptation of industrialized products to customer-specific requirements, building on significant operational experience.

- Development of new gamma ionization chambers with our experienced research and development teams.

- Long-term development, modelling and test collaborations with internationally renowned research organizations.

- Complete manufacturing and test processes on site.

- Support from all the Exosens group activities, experience, and knowledge.

- Highly regulated Quality Assurance programs adapted to the customer’s environment.

- Expertise in design and manufacture of nuclear instrumentation to solve customer challenges.

Main features

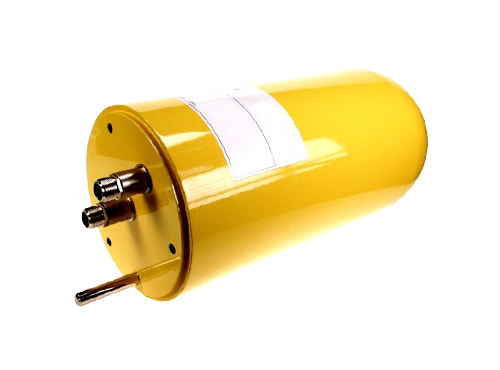

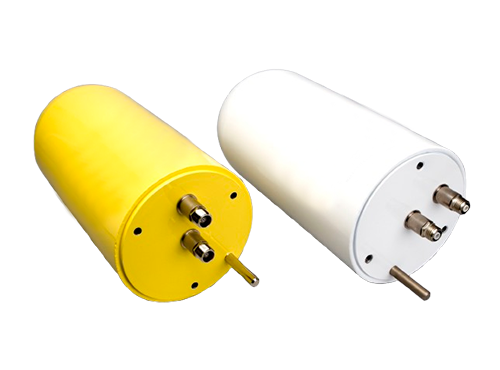

- Structure: One or two terminations.

- Electrodes: Various material types utilized, with options for guarded designs

- Filling gas: Multiple gas types and pressure options, subject to the required sensitivity and gamma energies.

- Insulators: Exosens only uses high-grade, radiation-resistant insulators from qualified suppliers to ensure the measurement of extremely low currents.

- Integral cable: Integral organic and mineral-insulated cable designs are available

Examples of Customization of Standard Parts

- Gamma energy and sensitivity tailored to individual application requirements.

- Customized connector type (BNC, HN, SHV and many others).

- Mechanical interfaces and assemblies.

- Ruggedized structure for harsh environment (radiation, temperature, humidity, mechanical stress).

Main features

- Structure: One coaxial mineral insulated cable connected to the detector.

- Electrodes: Two electrodes in a concentric stainless steel tube assembly.

- Filling gas: The gas type and pressure depend on the required sensitivity. Standard gases are nitrogen or xenon.

- Insulators: Exosens only uses high-grade, radiation resistant alumina insulators from qualified suppliers to ensure the measurement of extremely low currents.

References

The French Alternative Energies and Atomic Energy Commission (CEA) selected Exosens as its technological partner for a co-operative development of neutron and gamma detectors when the French nuclear power program took shape in the sixties.

Our references:

Fuel reprocessing plant – AREVA/COGEMA/ORANO – Numerous gamma ionization chambers – France, Japan.

THE INFLUENCE OF THE TYPE OF FILLING GAS ON THE RESPONSE OF IONISATION CHAMBERS TO A MIXED HIGH-ENERGY RADIATION FIELD, S. Mayer et al., Rad. Pro. Dos. (2007)